Key Strategies for Maximizing Productivity in Industrial Settings

Within manufacturing and industrial production, the specter of machine downtime looms large, casting a shadow over productivity, profitability, and operational efficiency. At the heart of this challenge lie several key factors that contribute to disruptions in production processes, each demanding careful consideration and strategic intervention to sustain uptime and optimize performance.

One of the primary culprits behind machine downtime is the phenomenon of equipment degradation and failure. Over time, machinery undergoes wear and tear, rendering it increasingly susceptible to malfunctions and breakdowns. Whether due to inadequate maintenance practices, suboptimal operating conditions, or aging infrastructure, equipment failures can precipitate costly downtime, underscoring the critical importance of proactive maintenance strategies and asset management protocols.

Moreover, human factors play a significant role in exacerbating the risk of downtime within industrial settings. Despite advancements in automation and technology, human error remains an ever-present challenge, with missteps ranging from operator errors to maintenance oversights capable of triggering disruptive downtime events. Understanding this, fostering a culture of safety, investing in comprehensive training programs, and implementing robust error-proofing mechanisms emerge as essential strategies for mitigating the impact of human fallibility on production processes.

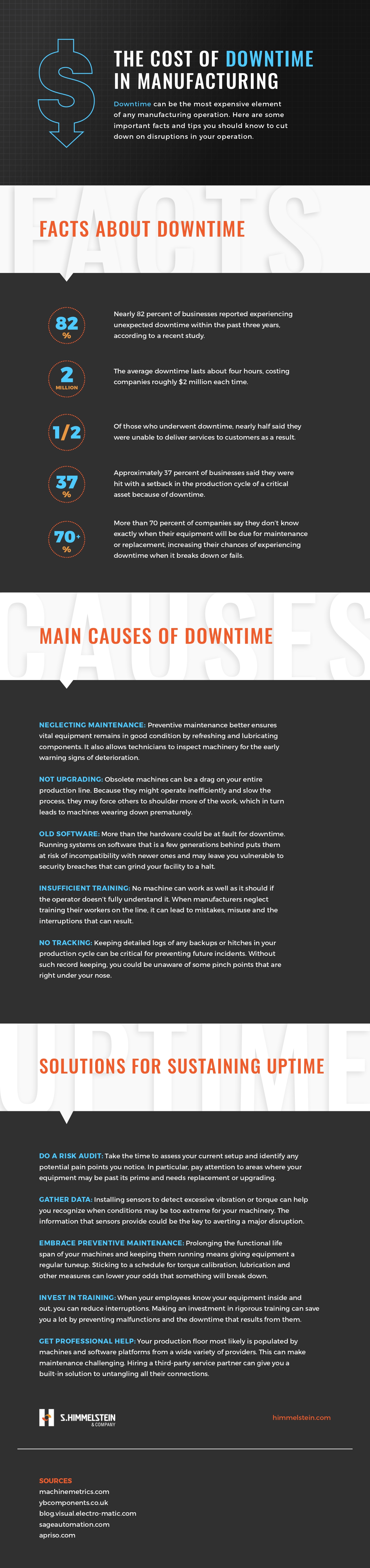

To learn more about the strategies organizations are utilizing to fortify their resilience, sustain uptime, and unlock new levels of operational excellence in today’s dynamic manufacturing landscape, please see the resource supported alongside this post

The Cost Of Downtime In Manufacturing, provided by S Himmelstein and Company, the organization to shop with for your next torque transducer