From Concept to Completion: Materials That Make It Happen

Behind every new product, building, vehicle, gadget or goods lies quality materials. The right materials make creations move from concept to reality. Manufacturers work closely with material suppliers to build prototypes and develop final products that function properly. There is constant innovation on both sides: suppliers develop advanced materials while manufacturers push material limits with new designs. Exciting material options exist today from smart polymers to eco-composites that make modern creations possible.

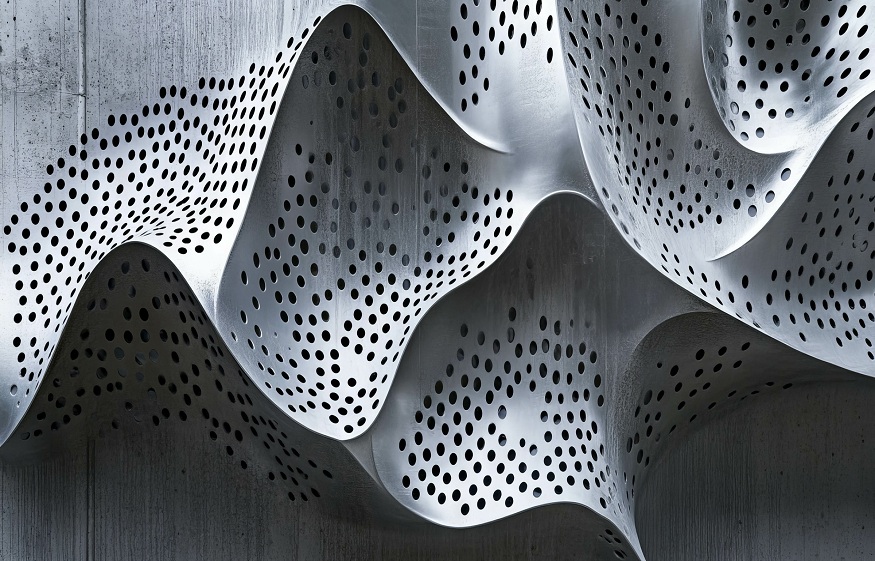

Strong and Lightweight Metals Expand Possibilities

Aluminum and titanium alloys allow manufacturers to make lighter, faster vehicles and structures. Aluminum parts replace steel ones in cars, trucks, trains and planes, for example. This cuts overall weight, boosting speed and efficiency. Lightweight titanium shows up in aircraft turbines, sports gear like bicycles or golf clubs, medical implants and even watches. Products made with these metals offer durability and performance in sleek, slimmed-down forms.

Engineers also reinforce plastics with carbon fiber for lightweight strength and stiffness. The material forms a matrix that can be molded precisely or layered for custom shapes. Carbon composites replace heavier metal components in racecars, rockets or satellites. Using these advanced materials, engineers push past old limits on product capabilities. But working with these tough metals and composites poses manufacturing challenges that require close collaboration between material experts and builders.

Polymers Offer Practical Magic

Many companies partner with EPS manufacturers like Epsilyte, who make polymers such as polystyrene. Polymers lend many modern convenience products their versatility. These long-chain molecule materials come in natural or synthetic varieties with differing qualities. Flexible and rigid polymers create soft squishy foams or solid durable plastics. Polymer gels give solid objects bouncy jelly properties, like in running shoe cushions. Manufacturers even make polymers change shape in response to conditions like heat or moisture.

Using polymer chemistry, material makers produce exactly what product builders need. For example, polymers create waterproof breathable membranes for athletic apparel. They provide impact protection and custom cushioning for prosthetics. Polymers help cosmetics feel and look flawless, insulate wires precisely and encapsulate medicine in programmable capsule forms. Their range seems endless thanks to ongoing polymer research and goal-specific formulation between material experts and product manufacturers.

Sustainable Materials Build Eco Options

Many manufacturers also want to incorporate eco-friendly materials as environmental awareness grows. Conscientious companies now consider sustainability from product concept stages onwards. Using recycled plastics, biodegradable polymers, responsibly sourced woods or natural fibers boosts green appeal. But properties of these eco materials can differ from standard ones, so adjustments may be necessary.

Some firms use bioplastics created by fermenting plant sugars rather than petrochemicals. These plastics have near identical qualities and processing abilities to normal ones, yet biodegrade safely. Manufacturers mold them into bottles, bags, medical items, phone cases, car parts and more. Hybrid composites like wood polymers let builders obtain natural material advantages along with easier processing and durability, and manufacturers make full use of recycled plastic, fabric, and metal scraps to reduce further resource demands.

Though sustainable materials currently represent a smaller market share, interest and availability continue to expand. Eco-conscious manufacturing aligns with shifting cultural priorities and often brings design innovations.

Conclusion

From concept to completion, manufacturers rely on material experts to realize product dreams. Alloys enable lighter and stronger builds, polymers add convenience through customization and sustainability goals are transforming material choices. Leveraging material science advancements as they happen means manufacturers push limits on what’s physically possible. But this also requires them to adjust familiar manufacturing methods to new material qualities during prototyping and production ramp up. Close collaboration between material suppliers and builders makes this a smooth transition. The synergy drives constant improvement on both material capabilities and manufacturing techniques.